Our Technology

PM-Wire TM

PM-Wire is a unique process for the design, manufacturing, and application of permanent magnets.

HIGHER PERFORMANCE

Higher efficiency, lighter, smaller, higher temperature operation.

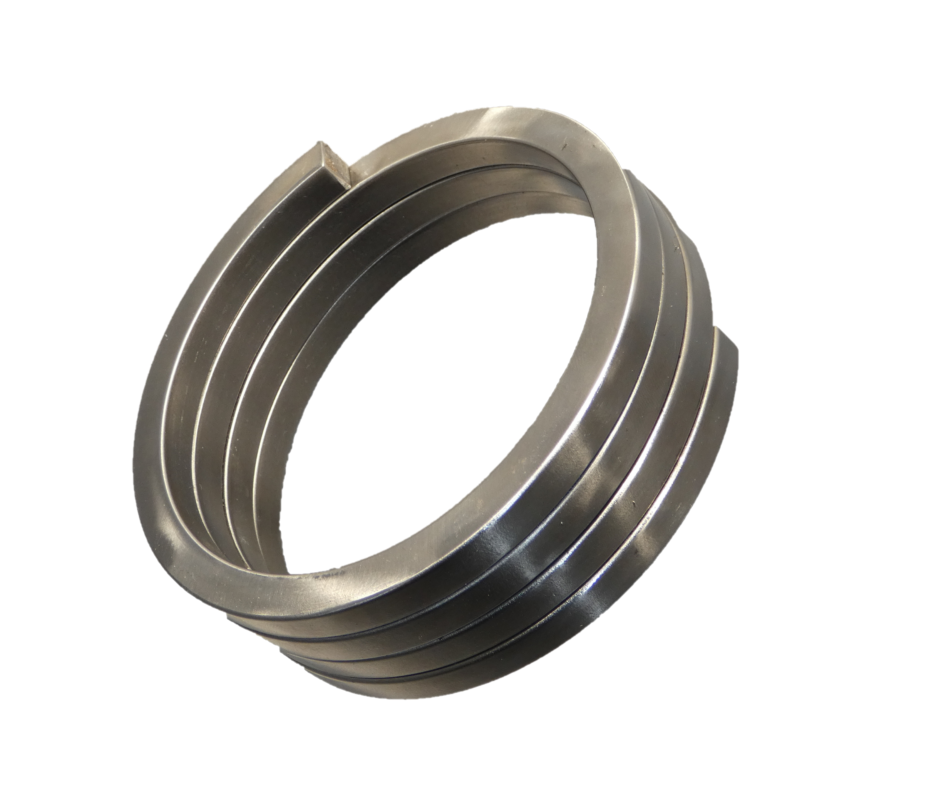

MANY CONFIGURATIONS

Long-length, rings, helixes, and much more.

LOWER COST

Performance equivalent to magnets using higher cost materials.

SUSTAINABLE MANUFACTURING

High-rate, high-yield manufacturing with domestically sourced materials.

Prototyping

AML has the experience to take an idea and design to prototype. Our facility includes capabilities for design, testing, and prototyping from magnet concept to a prototype.

Our Products

MAGNETS

Features include reduced weight, optimized performance, and ease of manufacturing and assembly.

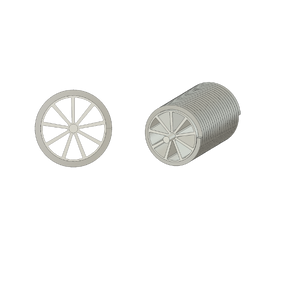

ROTORS

Novel assembly of permanent magnets with proprietary magnetization.

Our Technology Roadmap

Advanced Magnet Lab, Inc. (AML) was founded in 1995 as a research and development lab to develop magnet technology for particle accelerator applications. AML has since expanded through various programs across a number of applications in aerospace, renewable energy, transportation, and medical. For almost 30 years, AML has sought the 'holy grail' and today PM-Wire presents that opportunity for the world.

-

Jan 1, 2015

PM-Wire TM Conceived

The novel approach to manufacturing permanent magnets motivated by a need to lower the cost of magnet Halbach arrays for high-power density electrical machines.

-

Jan 1, 2018

PM-Wire TM - Phase 1

The concept was validated using isotropic bonded NdFeB compositions. Magnets having uniform magnetization were produced. Achieved optimum performance.

-

Jan 1, 2021

PM-Wire TM - Phase 2

Developed magnets having “continuously changing magnetization” (single-piece Halbach array) using anisotropic bonded NdFeB compositions. Achieved optimum performance.

-

Jan 4, 2022

PM-Wire TM Pilot Manufacturing Line

Completed the design, build and commissioning of an advanced PM-Wire™ Pilot Manufacturing. Funded by U.S. Defense Innovation Unit (DIU).

-

Jan 9, 2022

PM-Wire TM Non-Rare Earth

Validated PM-Wire™ as an enabler for manufacturing and achieving the performance required for the use of Non-Rare Earth magnets in applications such as EV motors.

-

Jan 1, 2023

PM-Wire TM - Phase 3

Develop sintered PM-Wire™ magnet configurations using anisotropic NdFeB compositions. Funded by U.S. Defense / Defense Logistics Agency.

-

Jan 1, 2023

Metal Alloy Development

Developing magnet alloy compositions which are optimized for performance and cost. Funded by REE Supply Chain Partner and the U.S. Defense Logistics Agency.

FAQ

These are some of the common questions that arise with the understanding of PM-Wire and its capabilities and uses with various applications.

Have more questions? You reach a member of our team by getting in touch and they will be happy to provide more information .